FOSTER ORTHODONTICS

3D printing technology means more accuracy in dentistry

If football is a game of inches, dentistry is a profession of millimeters.

And a Shreveport-Bossier dental practice has invested in making the most of those millimeters.

Foster Orthodontics claims to be the only practice in Louisiana using 3D printing when making appliances like braces, crowns and implants. 3D printing lets dentists make those appliances – and place them in your mouth – as accurately as possible.

“3D printing has gotten down to about 3,000ths of a millimeter,” said Dr. Ben C. Foster, who is in practice with his father, Dr. Ben E. Foster. “When you’re talking about a tooth that sometimes is five or six millimeters wide, a 10th or 100th of a millimeter makes a pretty big difference.”

The more accurate the appliance fits, the more effective it is – and in less time.

“Since I’ve been able to have 3D printing in our office, I would bet we’ve been able to knock consistently at least probably four months off treatment time in braces because of the accuracy in which you can place these braces.”

Dr. Foster explains how the process works:

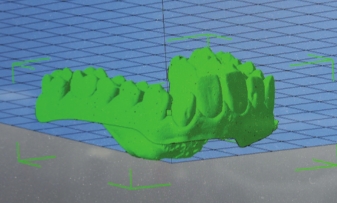

“We have a technician who does a scan. A patient will have a scan on their teeth done with a digital scanner. It basically looks like an oversized toothbrush. It takes thousands and thousands of images quickly. It compiles all of these images together and creates one large file that is the patient’s teeth – top teeth and bottom teeth. Then we take that digital file and print that model out on our 3D printer. We actually place brackets on those models because it’s so accurate.

I can do that in my office without the patient moving – without having to worry about contamination of saliva. I place that bracket in the exact appropriate position, and I don’t have to worry about if I got it right. Then, I take that bracket and basically make a transfer tray and I transfer it to the patient’s natural teeth in their mouth, and it is a 100 percent duplication of that.”

Foster

Orthodontics started using 3D scanning about eight years ago. Three and a

half years ago, Dr. Foster bought the practice’s first 3D printer. Dr.

Foster says at the time, Foster Orthodontics was one of only six dental

practices in the country to have a 3D printer. Since then, Foster

Orthodontics has added a second printer “because we are using it so

much.”

Foster

Orthodontics started using 3D scanning about eight years ago. Three and a

half years ago, Dr. Foster bought the practice’s first 3D printer. Dr.

Foster says at the time, Foster Orthodontics was one of only six dental

practices in the country to have a 3D printer. Since then, Foster

Orthodontics has added a second printer “because we are using it so

much.”

“It’s a very expensive piece of equipment,” Dr. Foster said. “But the reward you get and the accuracy and the perfection it provides way exceeds the cost of the machine in my eyes.”

And when you’re talking about making an appliance for someone to wear in his or her mouth, accuracy and perfection are very important.

“The error rate in a normal impression is about eight percent,” Dr. Foster said. “When you introduce an eight percent error rate – I wanted to eliminate that. When I saw this 3D printing, I said, hey, right there, that eliminates your error rate in your impression. Therefore, you’re going to get a better product from the start. You’re going to reach your end goals quicker, and you’re going to be more predictable. In my office, I love predictability and I love consistency, and that’s what this printer has been able to provide for me.”

A report last year in The Huffi ngton Post detailed how 3D printing is not only “making dentistry more affordable, customized and convenient for patients, but it’s also bringing back manufacturing work from overseas.”

The story claims dental laboratories in the United States “have been losing business for years to labs in Asia, where dental parts have been made by hand more cheaply.” However, the story said 3D printing technology is “bringing that business back to America.”

While

Dr. Foster is happy with his practice’s current use of 3D printing, he

hopes to expand its benefits, specifically when it comes to aligner

therapy. That’s the approach of using a series of clear dental

appliances that are formed to the shape of a patient’s teeth.

While

Dr. Foster is happy with his practice’s current use of 3D printing, he

hopes to expand its benefits, specifically when it comes to aligner

therapy. That’s the approach of using a series of clear dental

appliances that are formed to the shape of a patient’s teeth.

“I can have a software program that I am actually working with right now – doing some beta testing on – that I am actually physically changing positions of teeth in the software, and we can print that model out and we can start fabricating tooth movement using aligners in our office, where you won’t have to use a third party product like ClearCorrect or Invisalign,” Dr. Foster said. “Those are things we at Foster Orthodontics will be able to do inhouse, as the technology on the computer side catches up to the printer side.”

–Tony Taglavore