Caddo Bros.

Hats Off to Artistry!

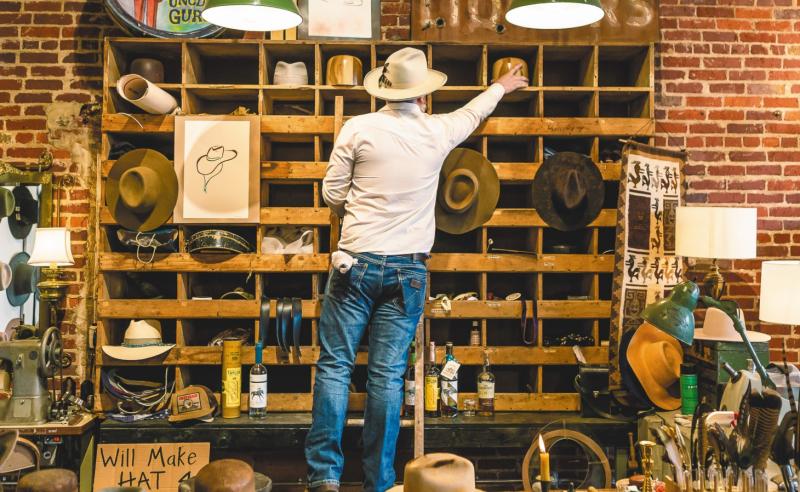

In the back corner of the family business, C&C Mercantile and Lighting, businessman, artist and just all-around cool guy Derek Simmons makes custom hats for the trendy and the traditional. Come along and visit his workshop with us and explore his exquisite craftsmanship. Get ready to be bowled over!

To say Lauren and Derek Simmons are artsy types would be a massive understatement. They took a decades-old family business known for its work in the electric and lighting industry and renamed, rebranded and relocated it into the area of downtown Shreveport which is quickly gaining a reputation as the arts and culture center of the city.

To say Lauren and Derek Simmons are artsy types would be a massive understatement. They took a decades-old family business known for its work in the electric and lighting industry and renamed, rebranded and relocated it into the area of downtown Shreveport which is quickly gaining a reputation as the arts and culture center of the city.

What originally was C&C Electric was opened in 1946 by the Camus family. Wayne and Gale Simmons acquired the company in 2003. In 2019, their son Derek and his wife, Lauren, bought the business and created C&C Mercantile and Lighting, moving to Texas Avenue just down the street from the Shreveport Police Department. On their website, Derek explained that they still repair and restore lighting, but they also do electric conversions, offer antique furniture and décor, as well as fine art jewelry and “guy stuff.”

They’ve also become a nexus of events, art receptions and get-togethers, even serving coffee on the weekends to downtown visitors.

Derek said the couple spends some of their evenings at the dining room table, brainstorming ideas. It was almost inevitable that the Simmonses’ love of nostalgia would lead them into the hat business, turning family heirlooms into restored treasures. Thus, Caddo Bros. Hat Company was born. It’s self-described as “a gentlemen’s brand crafted by local artisans using age-old methods.”

According to its website, “Caddo Bros. creates an environment that preserves American-made handcrafted goods such as hats and leather goods and was built by local craftsmen in Caddo Parish.”

The intersection of creativity, art and nostalgia are the hallmarks of everything about C&C Mercantile and its mission. The hat department is one small section in the middle of the building against an exposed brick wall, but there is no shortage on style.

As Derek explains it, “One of the other things we also dreamed up at the dining room table — and this was in 2019 — that we would start manufacturing hats the oldschool way. We’re hat people.

So, we found suppliers to buy rabbit and beaver blanks. Then we started buying hat blocks and molds. We got our steamer, got all our pieces together.”

Derek does most of the hat designing, shaping and fitting.

They offer one-on-one personal advice and guidance to customers to restore a family chapeau or create a new keepsake out of American sourced material. “We’ll look at textures and colors, brim styles, the crown shape. You really start picking it out. ‘I like the crown of this on and the brim of that one, you know?’ It’s basically to design the hat you want. It’s not off the shelf. It’s being made for you.”

He said most store-bought hats people purchase off the shelf are Merino wool made from sheep hair. He said it’s a thinner material with a different texture — most of their original products are constructed of rabbit or beaver.

He said most store-bought hats people purchase off the shelf are Merino wool made from sheep hair. He said it’s a thinner material with a different texture — most of their original products are constructed of rabbit or beaver.

The process begins with taking measurements. Then the customer starts making decisions about the color they want for their hat, the shape of the crown and the style of the brim. “[It’s] no different from going somewhere else and getting a suit fitted for you,” Derek said. “We get a lot of first-time hat wearers. Since we’re making it, you can do something sentimental. We have a young lady who brought us some of her grandmother’s old fabric. We cut that up, sewed it together and made it into the hatband. It’s sentimental. It means more than just some grosgrain ribbon.”

If you have an older hat, Simmons said you could bring it in, and they can reshape it to look right again. “We also do older restorations if you happen to have your dad’s or grandfather’s old hat. We get those all the time. People bring them in, and we clean them. We’ll put new sweatbands in them. We’ll also alter them.”

One woman brought in her father’s western hat, which they restyled to be more feminine and work for the customer. “We took the cowboy out of it, put extra stitching on it and changed out the hatband, and she was ecstatic,” he said.

“A lot of times we don’t go for a perfect hat. A lot of times [even a new hat] almost looks like it’s been restored. We’re selling nostalgia. We’re locking into people’s memories. There’s a reason. You’re trying to tie back into your roots.”

Once all measurements, material selection and style considerations are complete, the process of making the final hat takes around two weeks. “Normally, when [the customer] leaves, we block the hat. We trim it, and we trim it. It usually will not have a hat band on it, which is cosmetic,” Derek explained. “We’ll call the customer back in for a fitting to make sure everything is right, to make any adjustments, to get to see their hat on their head. If they want to make any changes, now is the time. If there are any adjustments or alterations to be made, we go ahead and make them. When they come back, the hat is finished, and we steam the hat for them.”

The steaming process is to make the final fit unique to the owner.

“That is a different process from just getting a hat off the shelf. When you have something made for you, the hat is pretty darn close to fitting you.” He said they use a process that heats the hat to a high temperature to make it pliable, and then it is put on the customer’s head to cool. “They put the hat on their head hot. We let the hat cool down on their head, then it matches. There is no perfect head. It may be close, but it will never be perfect until we match it to your head. That’s the last step of our process.”

As expected, a custommade hat that perfectly fits the customer will come at a price. But from the demand that they’ve experienced, the cost is worth the results. “A rabbit hat starts at $375 to $440. A beaver starts at about $550. We may sell a few more rabbit than beaver, but I’m currently sold out of beaver. We can’t keep beaver hats. Usually, people’s first hat is a rabbit. Second hat is almost always a beaver.”

The word is spreading about the little company. “Ben Ashby who owns Folk Magazine, did a story on us,” Simmons said. “He’s out of Kentucky. We don’t have any ties up there. Texas, Louisiana, Mississippi and Arkansas. That’s kind of our people. Halfway through 2021, the Discovery Channel, Chip and Joanna, reached out to us about being part of the Magnolia Network. They wanted to do some filming with us. They’re supposed to start back this spring.”

Also co-located with Caddo Bros. is another Simmons enterprise, a non-profit business called ArtiFact, which stands for Artisan Factory. They employ individuals with autism and Asperger’s Syndrome to help them make products using various methods, including a CO2 laser and a computer router. The laser allows them to do unique and personalized etching into the hat fabric.

“Using the machine next door, we also do burning under the brim. That’s really different for hat people. There’s really no one around in the hat world that’s burning in images underneath the brim of a hat.

We do scenes, personalization, things like that.” Etching is not their only twist in the process. Sometimes they actually set a hat on fire. “We’ll actually burn the hat, actually start burning the hair on the hat,” Simmons said. “Then we can rub it back down, and it leaves a patina. It looks like — I mean, the hat could be three days old, and it looks like it’s 45 years old. But it fits just like a new hat.”

So, suppose a new hat is in your future, or you’re only curious about a local place where you can get a hat made from scratch to your exact specifications and unique style. In that case, Caddo Brothers are ready and waiting inside C&C Mercantile on Texas Avenue. And after hours, Lauren and Derek Simmons are probably sitting around that dining room table dreaming up something else to get busy doing.

As Derek puts it, “Lauren and I pinch ourselves. It’s the random things we get to do and make a living doing it.”

https://www.facebook.com/caddobros/